Our Business and Products

Our Presence:

Orient Steel & Industries Limited (OSIL)has its units spread across the State of West Bengal and Haryana.

HARYANA UNIT – Ballabgarh

- Hot Rolled Strips & Plates.

- HR Mild Steel Strips of width 63 to 380mm, thickness 1.3 to 8.00mm which is used in making ERW Pipes and Industrial Pipes and also Cold Rolled Strips.

- HR Mild Steel Plates width 620mm x 30mm to 100mm thick in length ranging from 3 to 7 Mtr depending upon the thickness for industrial applications.

- HR High Carbon Steel Strips of C-60, C-80 & HC-21 grades are consumed by Cold Rollers for manufacture of Cold Rolled Hardened & Tempered Strips for making Hacksaw Blades, Band Saws, Chaff Cutters, etc.

- Hot Rolling of Stainless Steel of 202, 304 & 316 grades, Razor Blade Quality Steel, Soft Iron & Softmag are carried out on job work basis to customer’s specifications

- Cold Rolled Strips

- Cold Rolled Strips of width 15 to 417mm, thickness 0.4 to 3.0mm which is used for making auto components and white goods.

- Cold Rolling of Razor Blade Quality Steel, Soft Iron & Softmag are carried out on job work basis to customer’s specifications.

- Cold Roll Formed Sections for freight wagons and Coaches of Railways

- Cold Roll Formed Sections used in Freight Wagons type BCNHL, BOXNHL, BOXNR, BRN, etc and Coaches (Integral coach factory, Diesel Loco Works, Railway Coach Factory) of Indian Railways.

- Purlins in Z & C-Sections for pre-engineered buildings

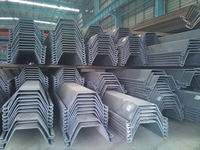

- Cold Formed Sheet Pilings in Z & U Sections

- Cold Formed Sheet Piles in ‘Z’ & ‘U’ shapes in different popular sizes upto 14mm thick made out of Hot Rolled Steel conforming to IS:2062 in E250, E350, E410 & E450 grades:

Sheet Piles Z-type Sheet Piles U-type

Sheet Piles are by definition, structural units which when connected one to another, will form a continuous wall, generally for retaining earth or excluding water. Individual pieces or pre-interlocked pairs are installed by driving them into the earth using impact hammers, vibrators or by water jetting. In functioning as a wall, the sheet piling acts as a beam under load and therefore requires the capability to resist bending. In certain applications, ability to resist bending is not important but strength of interlock is.

Sheet Piling is manufactured in three basic configurations "Z", "U", and "Straight". They can be formed either "Hot Rolled" or "Cold Rolled". A recent development to the industry is the production of some sheet piling shapes by the cold-forming process in which hot rolled sheet is fabricated into traditional sheet piling shapes. These new additions to product availability contain interlocks which are considerably different from the hot-rolled product. Manufactured from a hot-rolled coil of sheet, it is slowly fed through a series of rollers which gradually bends or forms the steel into its designated shape. Sheet Piles manufactured through cold forming process attain better physical properties and dimensional tolerances than compared to that manufactured by hot process. Apart from the advantage of higher section modulus, moment of inertia and sectional area per meter of wall there is advantage of 20% weight as well.

The "Z" type configuration for sheet piling is the strongest and most efficient. These shapes resemble wide-flange beams, having a web and two flanges. Since the interlocks are located out on the flanges at maximum distance from the neutral axis, a higher section modulus for resisting bending moments is provided. Z-Shapes have traditionally been used for deeper walls and heavier construction projects. However, they are now supplanting the arch or "U" shape for lighter work as more light-weight Z-shape have been introduced into the marketplace.

U-shapes resemble the hot-rolled channel sections produced on structural mills. The interlocks are formed on the web ends and interlock with their opposing mate along the centerline of the wall.

SIZES OF COLD FORMED SHEET PILES MANUFACTURED BY US:

Z Sheet Piles

| Type | Width (mm) | Height (mm) | Thickness (mm) | Sectional Area (cm2/m) | Weight (Kg/m) | Weight (Kg/m2) | Moment of Inertia (cm4/m) | Modulus of section (cm3/m) |

| OSZ | 400 | 185 | 8 | 175 | 40.20 | 100.50 | 12117 | 1310 |

| 400 | 185 | 9 | 185 | 45.21 | 113.02 | 13364 | 1474 | |

| 400 | 185 | 10 | 205 | 50.55 | 126.37 | 15150 | 1637.77 | |

| 650 | 429 | 8 | 90.2 | 63.80 | 159.5 | 43293 | 1980 | |

| 650 | 429 | 9 | 101.1 | 71.60 | 179 | 48521 | 2220 | |

| 650 | 429 | 10 | 112.0 | 79.20 | 198 | 53709 | 2450 | |

| 675 | 392 | 6.5 | 70.5 | 51.30 | 128.25 | 27251 | 1370 | |

| 675 | 392 | 7 | 76.1 | 55.16 | 137.9 | 29281 | 1470 | |

| 675 | 392 | 8 | 86.9 | 62.80 | 157 | 33350 | 1670 | |

| 685 | 392 | 8.5 | 92.1 | 67.70 | 169.25 | 35558 | 1780 | |

| 685 | 392 | 9 | 97.6 | 71.50 | 178.75 | 37580 | 1880 | |

| 685 | 392 | 10 | 108.4 | 79.20 | 198 | 41601 | 2070 |

Note: Any other size against specific requirement shall be manufactured upto 14mm thickness.

| Type | Width (mm) | Height (mm) | Thickness (mm) | Sectional Area (cm/m) | Weight (Kg/m) | Weight (Kg/m2) | Moment of Inertia (cm4/m) | Modulus of Section (cm3/m) |

| OSU | 450 | 360 | 8 | 148.6 | 48.29 | 107.34 | 18987.92 | 1055 |

| 450 | 360 | 9 | 165.9 | 54.62 | 120.164 | 21058.96 | 1170 | |

| 450 | 360 | 10 | 182.9 | 61.14 | 135.88 | 22767.97 | 1265 | |

| 575 | 360 | 8 | 133.8 | 56.14 | 97.68 | 200026.8 | 1113 | |

| 575 | 360 | 9 | 149.5 | 63.46 | 110.37 | 22221.36 | 1245 | |

| 575 | 360 | 10 | 165.0 | 70.71 | 122.91 | 24583.4 | 1368 | |

| 600 | 360 | 8 | 131.4 | 57.71 | 96.21 | 20887.3 | 1160 | |

| 600 | 360 | 9 | 149.5 | 65.22 | 112.76 | 23034.75 | 1280 | |

| 600 | 360 | 10 | 182.4 | 72.67 | 121.11 | 25102.82 | 1395 | |

| 650 | 480 | 8 | 138.5 | 67.54 | 103.82 | 40032 | 1668 | |

| 650 | 480 | 9 | 156.1 | 76.41 | 117.54 | 45241.1 | 1885 | |

| 650 | 480 | 10 | 179.1 | 85.11 | 130.98 | 46515.15 | 1935 |

Note: Any other size against specific requirement shall be manufactured upto 14mm thickness.

Application of Cold Formed Sheet Piles:

- Construction of docks and ports

- Waterways

- Breakwater

- Protection of river banks and channels

- Protection of construction pits in soil and water

- Bridge embankments

- Retaining walls

- Foundations

- Underground parking

- Underpasses, ramps and tunnels

- Slope protection

- Environmental protection and rubbish dumps

- Noise barriers

- Enclosure of contaminated soils

- Civil and industrial sites

- Civil defense

- Military engineering

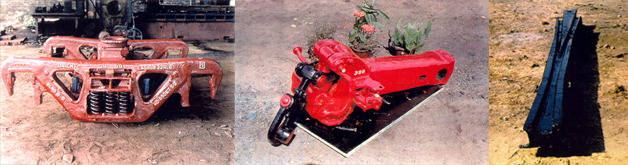

- Manufacturing MS, Carbon, Alloy and Manganese Steel Castings like bogies, couplers and CMS Crossings for the Indian Railways and other castings for the Engineering Industry.

- Pioneers in India for manufacture of Steel Shots & Grits

Steel Shot

Steel Shot is manfactured from electric melted basic Steel with a minimum carbon content of 0.85% cast by an exclusive process and then heat treated to a tempered martensitic micro structure.

Average hardness provided is 400-500 VPN (about 40-48 Rockwell C) as this hardness has generally been proved to be ideal for efficient and economic blast cleaning operations. special hardness can, however, be tailored upon request.

The exclusive casting process ensures that the Shot is perfectly spherical, free from 'Fish-tails' and hollows, the density of the shot being over 7.3 grams/cc.

Advantages

RESISTANCE TO BREAK-DOWN-Ten or more times that of iron shot. Two or more times that of malleable shot.

REDUCES MACHINE MAINTENANCE EXPENSE-up to 50% or more.

MORE ATTRACTIVE FINISH-Leaves no carbon deposit or metallic residue or imbedment.

Reduces storage, handling, freight, dust disposal expense.

|

Cleaning Shot Numbers

and Screening Tolerances | ||||||||||

|

Orient Shot No. |

S. A. E. Shot number |

Max. % retained |

Screen number and aperature in

mm. |

Max% retained |

Screen number and aperature in

mm. |

Min % retained |

Screen number and aperature in

mm. |

Max% retained |

Screen number and aperature in

mm. |

Max % to pass |

| 0 | S-930 | 0 | 6 (3.35) | - | - | 90 | 8 (2.40) | 7 | 10 (2.00) | 3 |

| 1 | S-780 | 0 | 7 (2.80) | - | - | 85 | 10 (2.00) | 12 | 12 (1.68) | 3 |

| 2 | S-660 | 0 | 8 ( 2.40) | - | - | 85 | 12 (1.68) | 12 | 14 (1.40) | 3 |

| 3 | S-550 | 0 | 10 (2.00) | - | - | 85 | 14 (1.40) | 12 | 16 (1.20) | 3 |

| 4 | S-460 | 0 | 10 (2.00) | 5 | 12 (1.68) | 80 | 16 (1.20) | 11 | 18 (1.00) | 4 |

| 5 | S-390 | 0 | 12 (1.68) | 5 | 14 (1.40) | 80 | 18 (1.00) | 11 | 20 (0.85) | 4 |

| 6 | S-330 | 0 | 14 (1.40) | 5 | 16 (1.20) | 80 | 20 (0.85) | 11 | 25 (0.70) | 4 |

| 7 | S-280 | 0 | 16 (1.20) | 5 | 18 (1.00) | 80 | 25 (0.70) | 11 | 30 (0.60) | 4 |

| 8 | S-230 | 0 | 18 (1.00) | 10 | 20 (0.85) | 75 | 30 (0.60) | 12 | 35 (0.50) | 3 |

| 9 | S-170 | 0 | 20 (0.85) | 10 | 25 (0.70) | 75 | 40 (0.42) | 12 | 45 (0.35) | 3 |

| 10 | S-110 | 0 | 30 (0.60) | 10 | 35 (0.50) | 70 | 50 (0.30) | 10 | 80 (0.18) | 10 |

Steel Grit

Steel Grit is manufactured from solid Steel Shot by fragmenting it into sharp angular grit. Thus the steel grit is a product of the same tough resilient steel as our Steel Shot. It is heat-treated also to yield a product consistent with the ideal quality requirements.

|

Cleaning Grit Numbers

and Screening Tolerances | ||||||||

|

Orient Grit No. |

S. A. E. Grit number |

Max. % retained |

Screen number and aperature in

mm. |

Max% retained |

Screen number and aperature in

mm. |

Min % retained |

Screen number and aperature in

mm. |

Max% to pass |

| 1 | G-12 | 0 | 8 (2.40) | 80 | 12 (1.68) | 10 | 14 (1.40) | 10 |

| 2 | G-14 | 0 | 10 (2.00) | 80 | 14 (1.40) | 10 | 16 (1.20) | 10 |

| 3 | G-16 | 0 | 12 ( 1.68) | 75 | 16 (1.20) | 10 | 18 (1.00) | 15 |

| 4 | G-18 | 0 | 14 (1.40) | 75 | 18 (1.00) | 10 | 25 (0.70) | 15 |

| 5 | G-25 | 0 | 16 (1.20) | 70 | 25 (0.70) | 10 | 40 (0.42) | 20 |

| 6 | G-40 | 0 | 18 (1.00) | 70 | 40 (0.42) | 10 | 50 (0.30) | 20 |

| 7 | G-50 | 0 | 25 (0.70) | 65 | 50 (0.30) | 10 | 80 (0.18) | 25 |

| 8 | G-80 | 0 | 40 (0.42) | 65 | 80 (0.18) | 10 | 120 (0.12) | 25 |

| 9 | G-120 | 0 | 50 (0.30) | 60 | 120 (0.12) | 10 | 200 (0.07) | 30 |

| 10 | G-200 | 0 | 80 (0.18) | 55 | 200 (0.07) | 10 | 325 (0.04) | 35 |